液龙机械

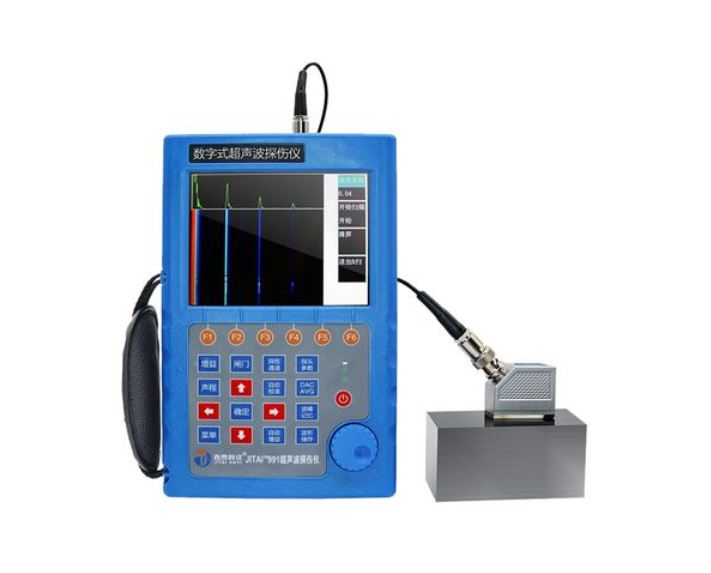

Digital Ultrasonic Flaw Detector

Digital Ultrasonic Flaw Detector is a portable industrial non-destructive testing instrument, which can detect, locate, evaluate and diagnose various defects (cracks, porosity, pores, inclusions, etc.) inside the workpiece quickly, conveniently, without damage, and accurately. It can be used in both laboratory and engineering field. Widely used in boilers, pressure vessels, aerospace, aviation, electric power, petroleum, chemical industry, offshore oil, pipelines, military industry, shipbuilding, automobiles, machinery manufacturing, metallurgy, metal processing industry, steel structure, railway transportation, nuclear power, universities, etc. industry.

Features

(1) The detection speed is fast. Generally, digital ultrasonic flaw detectors can automatically detect, calculate and record, and some can automatically perform depth compensation and automatically set the sensitivity, so the detection speed is fast and the efficiency is high.

(2) High detection accuracy. The digital ultrasonic flaw detector performs high-speed data acquisition, quantification, calculation and discrimination of analog signals, and its detection accuracy can be higher than the detection results of traditional instruments.

(3) Record and file inspection, digital ultrasonic flaw detector can provide inspection records up to defect images.

(4) High reliability and good stability. The digital ultrasonic flaw detector can collect and store data objectively, process or post-process the collected data in real time, analyze the signal in time domain, frequency domain or image, and classify the workpiece quality through pattern recognition to reduce The influence of human factors is eliminated, and the reliability and stability of retrieval are improved. The main functions that can be realized are:

a. Automatic calibration: Automatically test the "zero point", "K value", "leading edge" of the probe and the "speed of sound" of the material;

b. Automatically display defect echo position such as: depth d, level p, distance s, amplitude, equivalent dB, aperture ф value;

c. Freely switch the ruler;

d. Automatic recording of flaw detection process and dynamic playback;

e. Automatic gain, echo envelope, peak memory function;

f. Flaw detection parameters can be automatically tested or preset;

g. Digital suppression, does not affect gain and linearity;

h. Multiple independent flaw detection channels, which can freely input and store flaw detection standards of any industry, and do not need to carry test blocks for on-site flaw detection;

i. Free storage and playback of waveforms and data;

j. DAC and AVG curves are automatically generated and can be produced in sections, with unlimited sampling points, and can be corrected and compensated;

k. Free input of various industry standards;

l. Communicate with computer, realize computer data management, and export flaw detection report in Excel format and A4 paper;

m. Real-time clock record: tracking record and storage of real-time flaw detection date and time;

n. Gain compensation: Db attenuation caused by factors such as surface roughness, curved surface, and long-distance flaw detection of thick workpieces can be corrected;

All of the above functions cannot be achieved by analog ultrasonic flaw detectors.